Brand Name: Weibo Technology

Model No. JZ-DX500

E-mail : jzfsj@126.comI. Purpose

The JZ—DX500 production line is mainly used to process oil-free wires such as communication wires, automobile wires, computer wires, household wires, etc. The materials are regenerated into recyclable metal particles and plastic particles respectively through a secondary crushing and tertiary separation process.

II. Process Introduction

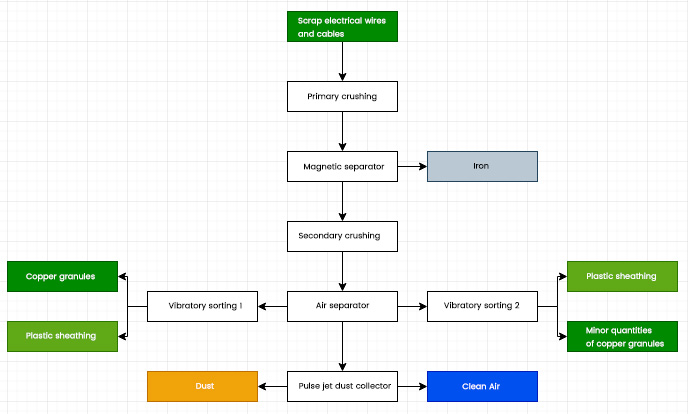

First, the manually pre-sorted materials (oil-stained or unknown materials are strictly prohibited) are sent to the first-stage crusher. The first crusher adopts tear crushing method. After the materials are coarsely crushed, they fall into the belt conveyor and are sent to the second-stage crusher by the conveyor. Among them, the first crusher discharge conveyor is equipped with a belt magnetic separator Lock the magnetic material in the material in advance.

The second crusher adopts the hammer crushing principle. After the material is finely crushed, it falls onto the screw conveyor through the screen and is sent to the air flow for sorting by the conveyor

Depending on the specific gravity of the materials, the airflow sorter uses airflow and vibration to move the materials with higher specific gravity to higher heights, while the materials with lower specific gravity flow from lower heights. The metal mixture coming out of the high part of the airflow sorter falls onto the No. 1 vibration sorter, while the plastic skin mixture coming out of the low part falls onto the No. 2 vibration sorter

No. 1 vibratory sorting passes through the screen to separate the copper particles and a little plastic skin, and No. 2 vibratory sorting passes through the screen to separate the plastic skin and a little fine copper wire. Different vibrating screens can be set for different materials, so that the purity of the separated metal particles can reach more than 97%;

The production line has designed a dust removal system. The dust generated in the second crushing, air flow sorting and material transportation enters the pulse dust collector through negative pressure vacuuming for dust treatment, releasing clean air, which fully complies with the national atmospheric emission standards.

III. Process Flow Chart

IV. Equipment Features

1. Compact structure, beautiful appearance, reasonable layout, easy installation, simple and practical.

2. PLC control, intelligent operation, smooth operation of equipment, saving time, effort and worry.

3. The crusher, sorting equipment and dust collection equipment adopt platform combination, which is convenient for movement and transportation.

4. The pulverizer rotor adopts alternating knife shafts, which makes the pulverizer more efficient, quieter and more stable.

5. The pulse dust removal equipment effectively controls dust overflow and has a dust removal efficiency of up to 99%.

V. Whole machine parameters

| Equipment Model | JZ-DX500 |

| Total power | 67KW |

| Form factor | 9990*4100*3320 |

| Processing volume | 300-500KG/H |

| Power of first stage crusher | 11KW |

| Secondary crusher power | 37KW |

| Sorting method | Airflow & Vibration |

| Control method | Smart Touch Screen |

| Dust removal method | Wind pressure dust removal |

*Appearance dimensions are based on design drawings

Equipment configuration can be adjusted according to actual needs