Brand Name: Weibo Technology

Model No. JZ-GCB400

E-mail : jzfsj@126.com1. Process flow chart:

2. Equipment Introduction:

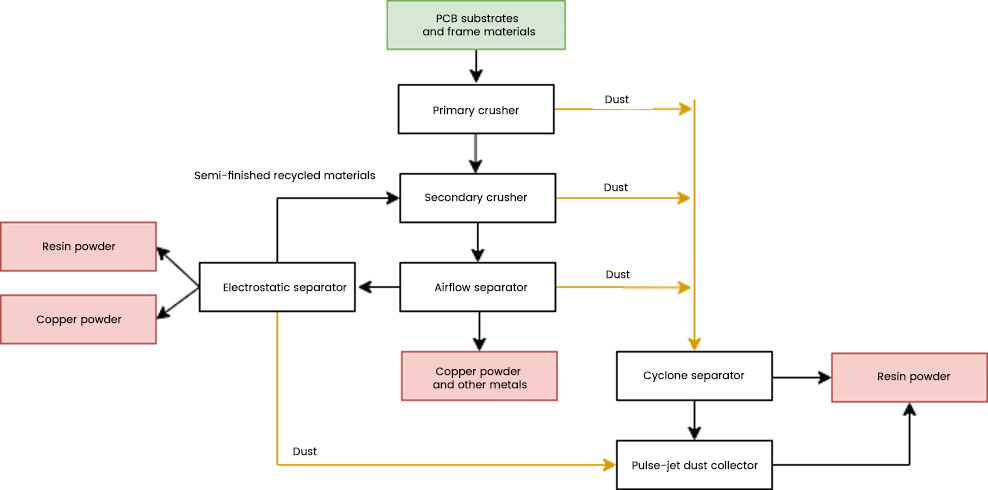

Due to the special physical properties of waste circuit boards, this equipment adopts dry crushing and sorting processes for the recycling of waste circuit boards, so that they can be recycled into recyclable metal powder and resin fiber powder respectively. First, the waste circuit board is coarsely crushed and then crushed to make it into a powdered mixture of metal and resin fiber powder; then through wind sorting, the metal components are separated from the resin, and dual electrostatic sorting equipment is used to further finely separate the semi-finished products and resin powder, thereby improving the equipment sorting rate and reducing losses. In order to prevent dust pollution during the regeneration process, a pulse dust removal device is installed after the wind sorting process, which effectively solves the dust pollution.

3. Main parameters:

| Device Name | JZ-GCB400 waste circuit board recycling line |

| Equipment Model | JZ-GCB400 |

| Equipment for handling materials | Waste circuit boards, border materials, and corner materials |

| Treatment volume (kg/h) | 300-400 |

| Total power (kw) | 122.24 |

| Apparatus form factor (mm) | 9330mm×11400mm×5200mm (depending on actual situation) |

| Equipment performance and features | 1. Compact structure, reasonable layout, stable performance and low noise. 2. PLC is used to control the uniform feeding and coordinated operation of the full production line. 3. The entire production line uses negative pressure feeding to effectively reduce dust overflow. 4. The equipment sorting rate is as high as 98%. 5. The pulse dust removal equipment has an efficiency of up to 99.99%. 6. High-voltage electrostatic sorter makes sorting more fine and efficient, effectively controlling non-ferrous metal loss. |