Brand Name: Weibo Technology

E-mail : jzfsj@126.com1. Process Introduction: This equipment uses a plasma arc to melt and crack the material to be treated. The principle is to use the high temperature of hot plasma to decompose the organic matter in solid waste into hydrogen-rich gas and a small amount of acidic gas in an oxygen-free environment; the metals in the waste melt and the discharged furnace body can be recycled; after the inorganic matter melts, the discharged furnace body cools and becomes lava-like glass.

The center temperature of the torch is around 3000 ℃to 10000℃. This equipment is a complete production line with an exhaust gas treatment device, and the exhaust is clean and harmless gas.

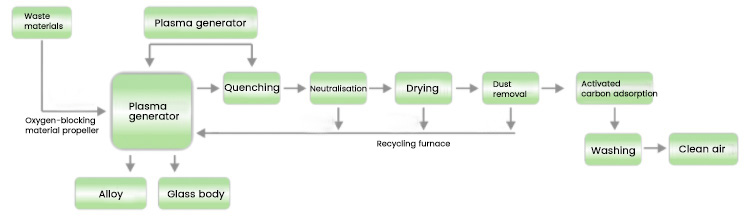

2. Process Flowchart:

3. Equipment Features:

1. Processable waste, including organic, inorganic, hazardous or non-hazardous gases, liquids and solids.

2, safely and irreversibly dispose of all waste products and convert them into valuable commodities.

3. It can achieve higher environmental protection requirements and achieve zero emissions.

4, 300:1 ultra-high reduction capacity.

5, Small footprint, simple operation and maintenance.

6, Plasma cracking furnace can reduce treatment cost and environmental responsibility.

7. The plasma generator replaces the hollow graphite electrode generator, avoiding the consumption of graphite materials during work, which causes cumbersome operation and large heat energy loss, leading to the overflow of toxic and harmful gases, secondary pollution and other defects in the workshop. Ensure the safety and reliability of the entire system in operation.

8. The furnace body is built with special ultra-high temperature refractory materials, and the feed adopts a special sealing method to ensure that the furnace is in a negative pressure reducing atmosphere to completely melt and crack organic and inorganic toxic and harmful wastes, perform rapid cooling, and neutralize and deacidify acids and alkalis. Dust removal. The adsorption purification system is safely emptied, and the glass and metal melt are discharged from the furnace body from their respective channels.

9. We have independently developed a purification system and fly ash recovery device to further treat the reacted gas, effectively avoiding the pollution of the environment by toxic and harmful gases and fly ash, and fully complying with the country's environmental protection requirements "Comprehensive Emission Standard for Air Pollutants" GB16297—1996.

10. The furnace roof uses an endoscopic high-temperature industrial TV to monitor the interior of the furnace in real time, and to understand the reaction process inside the furnace at any time, such as the furnace rising and other phenomena. Compared with the past, it reduces the losses caused by blind operation of operators and enhances work efficiency.